Achieving impeccable welds is a hallmark of quality craftsmanship, and at MITUSA, we recognize the critical nature of high-caliber welds, especially when dealing with diverse materials. This detailed guide aims to share with you the most effective strategies to avoid welding defects, ensuring your welds are both robust and flawless.

Understanding Welding Defects: The occurrence of welding defects can be attributed to several factors such as incorrect welding methods, insufficient material preparation, and the inherent characteristics of the different materials being welded. These imperfections can undermine the structural soundness and functionality of your welds. To produce perfect welds, it’s imperative to anticipate and tackle these issues proactively.

-

Comprehensive Material Analysis and Selection Every material comes with its unique set of properties like thermal conductivity, melting points, and rates of expansion. Prior to embarking on any welding task, a detailed analysis of the materials to be joined is indispensable. Such an analysis helps you choose the most suitable welding procedure, filler materials, and welding parameters, promoting a seamless integration of the metals.

-

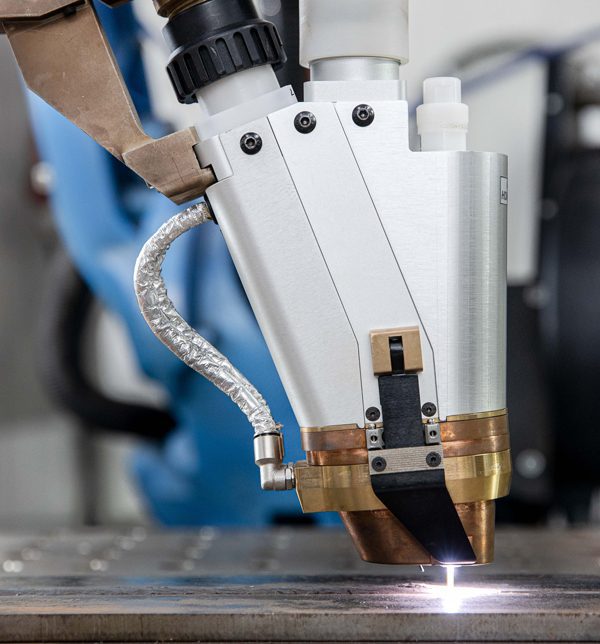

Appropriate Welding Technique and Parameters The choice of the right welding technique and parameters is crucial when dealing with a variety of materials. Modifying factors like heat input, travel speed, and electrode dimensions according to the material properties can prevent common issues such as overheating, warping, and insufficient bonding. At MITUSA, we provide expert advice to refine your welding approach for exceptional outcomes.

-

Immaculate Material Preparation The welding process starts with proper preparation of the base metals. Cleaning and degreasing the materials thoroughly eliminates potential contaminants that may lead to welding defects. Accurate beveling and aligning of the joint edges are also fundamental for achieving deep penetration and fusion during welding, which in turn strengthens and stabilizes the resulting weld.

-

Metallurgical Compatibility Welding together materials with different metallurgical properties can be challenging. It’s crucial to understand how different materials interact to avoid defects such as cracking, porosity, and embrittlement. Using compatible filler materials and suitable preheating methods can address these issues, substantially improving the quality of the weld.

-

Shielding Gas and Flux Considerations In welding processes like MIG and TIG, the selection of shielding gas or flux is key to defect prevention. The right choice helps establish a protective barrier around the weld pool, safeguarding it from environmental contamination and reducing the likelihood of defects like porosity and oxidation.

Conclusion: Recognizing the specific challenges posed by various materials and adopting effective preventative strategies is essential for achieving seamless and durable welds. MITUSA is your partner in this journey, providing expert welding advice, premium materials, and unwavering support to take your welding projects to the next level.

At MITUSA, we are committed to being your trusted ally in welding excellence. Our dedication to quality, expertise, and innovation sets us apart in the industry. We offer an extensive selection of welding materials, such as filler rods, electrodes, and fluxes, all engineered to optimize your welding process and help you attain perfect welds every time.