Internal Fuel Tank Seam Welder

Internal Fuel Tank Seam Welder

Our fuel tank trailer seam welder machine is engineered to ID weld seam tank cylinders. The are used for over the road tanker trucks, that transport gas, petrol fuel and other fluids. Designed for joining the vessel cylinder seam together using the internal fuel tank longitudinal seam welding GTAW process.

Our vessel seam welder designs are proudly manufactured in The United States of America. MITUSA builds the highest quality longitudinal seam welding machines for long large truck trailer vessel applications. The truck trailer tank cylinderical linear welding system is manufactured for domestic and international fuel tanker trucks.

Single pass one hundred percent full penetration ID welds using our internal longitudinal welding machine for tanks. Our complete seamer system includes material handling equipment providing the operator an easy ergonomic loading and unloading of the vessel tank in position on the seamer mandrel tooling ready for the tank’s seam welding joining process has been completed.

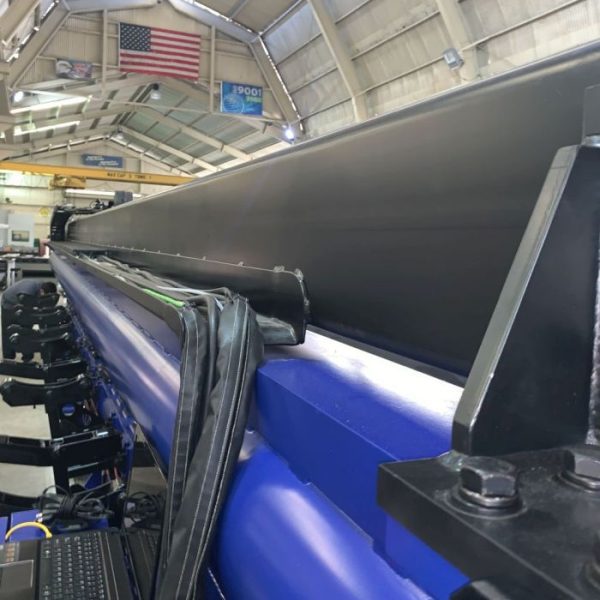

Linear View of the Seamer Bed

The cylinder part loaded and unloading is automated with our material handling tooling. This makes for a complete automated tank seam welding operation. This system is designed for I.D. linear seam welding on tanker fuel trucks or petrol vessels. MITUSA builds standard and custom automated longitudinal welding equipment for long large arc seam welding applications.

This advanced complete seamer system that can be customized for your specific welding application. This fuel tank seamer model was built for a petrol fuel tank truck length of 28 ft. Tank seam welding automation up to 40 feet of vessel seam welding length.

Using our ergonomic automated seam weld technology for easy operator material handling loading to align the seam weld joint over the seam welder bed mandrel and copper insert. Proprietary internal clamping tooling sets the edge perfectly for the TIG welding process to glide easily over the weld joint, providing high quality 100% penetration welds.

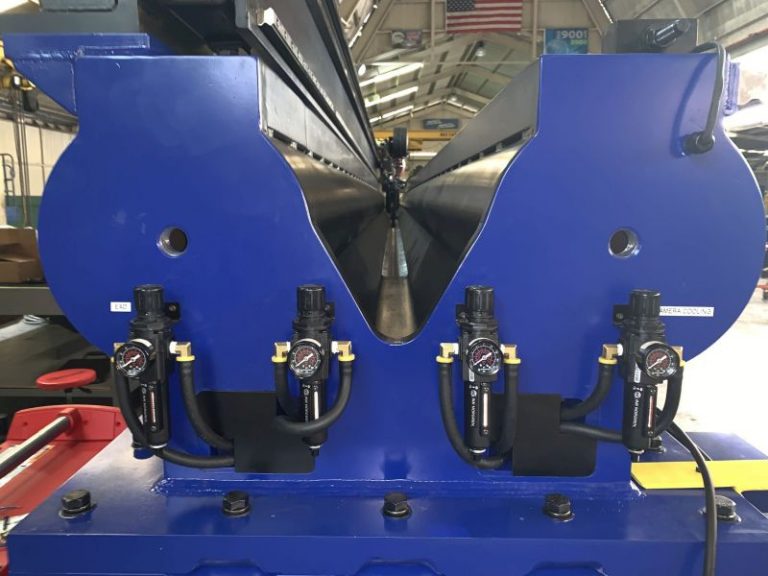

Internal ID Seamer Bed View

Xiris Arc Welding Camera System

All of our large linear welding machine systems are integrated with arc welding automation equipment and power supplies of your choice. We install Miller, Lincoln, Fronius, EBAB, K-Tec, OTC and more! Dressed out with Xiris welding cameras, Arc Products, Cyclomatic, CWT automation technology or other welding automation equipment controllers for a complete automated tank seam welding operation.

Systems for seam welding are incorporated with welding power supplies and feeders from manufactures such as Miller Electric, Lincoln, EBAB, Hobart, Fronius, OTC, Thermal Arc, K-TIG or the welding machines of your choice.

Vessel Welding Automation System

Truck Trailer Tank Seam Welding System

Our longitudinal weld seamers use precision linear rails with bearing blocks for a smooth seam weld is made along the clamped butt joint. Our linear tooling design gives the track a strong hold and allows free precise travel car movement or exact location on the side beam travel carriage.

Carriage travel car with smooth movement, ensuring the highest quality welds. The linear travel track is machined to a 0.005-in straightness tolerance so that the seam weld is as straight as possible based on the joint preparation. Precision weld seamers are designed for longitudinal welding of all types of metals with 100% penetration welds.

Precision Quality Custom Longitudinal Seam Welding Machine Designs

Seam Welding Cable Management

MITUSA arc seamers are designed with productivity and better operator safety. The easy maintenance design and usability allows high quality longitudinal seam welding machine production. Tooling replacement is made quite easy with operator accessibility, including simple loading and unloading parts material handling features. MITUSA engineers manufacture and build our seam welders for customer’s maximum ROI.

This massive over the road petrol tank seam welding machine system is designed to be used with or without our proprietary material handling tooling. This allows easy loading and unloading up to a 30′ long fuel tank shells easily onto the seam welder longitudinal seamer bed. This provides linear precision 100% penetration seam welds of the vessel butted joint fuel tank.

You can expect the best, more than what you expected, when MITUSA builds your large or small custom automated seam welder system. Customer service satisfaction is what MITUSA is all about when providing welding automation seam welding systems.