Planisher Equipment

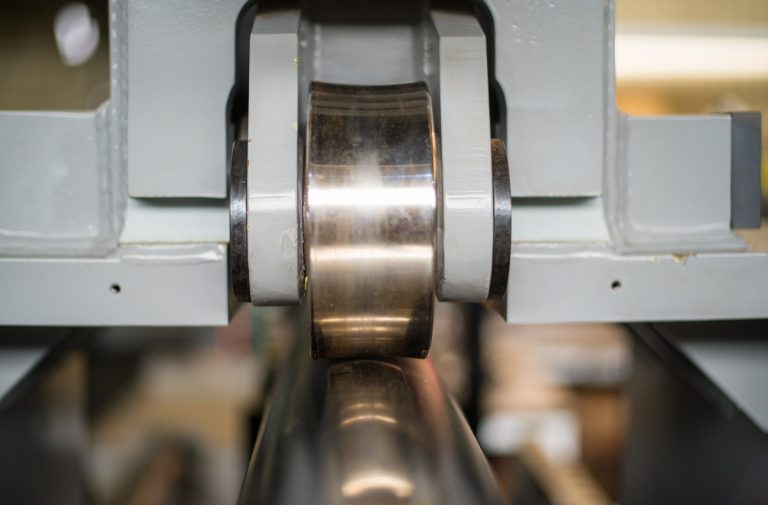

Roll Planisher Wheel Face

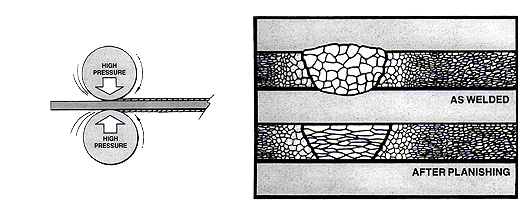

Planishers uses up to 20,000 pounds of pressure between the hard steel roller with the tooling mandrel support to smooth the weld crown and strengthen the seam weld bead. The intense force between the hardened steel roll and tool steel mandrel eliminates the seam weld bead by blending it into the base metal. Furthermore the final planished seam weld surface will appear as a seamless part. Planisher machine provide custom tooling that holds the supported part while the longitudinal seam weld bead is crushed between the hardened roller and linear mandrel. Seam weld planishing is done on automated longitudinal planisher systems. Some planishers using a PLC programmable control that allows variable pressure settings to smooth the weld seam bead into the base metal.

Planishers blend the OD/ID part finish weld seamlessly smooth.

The weld planishing process is a safe fast way to smooth out a weld bead and blend it for a seamless finish look.

The roll planisher uses a hardened steel metal roller to flatten and eliminate the seam weld bead crown smooth into base metal material. The roll wheel is mounted to an powered travel carriage where extreme pressure between the part and planisher mandrel tooling.

The amount of intense force created between the planishing machine roll and tooling smooths the weld bead for a cosmetic blend appearance.

During linear planishing production the welded part is mounted on the custom mandrel where it remains stationary during the planishing process.

Engineered to provide a full range of part shapes and sizes that can be planished using a combination of different roller wheel surface profiles and custom mandrel geometries for the correct part support.

Planished welds are stronger and blend cosmetically into the base metal

Planisher Machines Systems

Bellows Weld Planishers

Planishing welds is used to eliminate the costly time-consuming manual grinding and polishing labor, and material costs currently now used to finish seam welds. Linear planishers use new roll technology to ensure the operator safety during the parts finishing process. Safe hands free longitudinal planisher machines for planishing tube surface finish smooth.

Using proper sized planisher harden steel tooling roll and solid tool steel mandrel to prevent the OD/ID part size change. The planishing wheel force cold works by blending to eliminate the weld crown into a seamless weld appearance with adjustable pressure without distorting your parts size.

The motorized longitudinal planisher gantry carriage travels on four linear rail bearing blocks. Powered by a 2 Hp electric motor, the carriage contains an 8 inch/203 mm stroke air ram pump. The hand wheel is used to adjust the ram’s travel. Our automated planisher has special control panel features, plus an a operator safety screen made of expanded metal.

Information on how our advanced automated tube and bellows planisher systems provide the highest quality and safety of any thin metal roll planisher built today. MITUSA has the newest planisher technology for engineering and building custom planishers.

Gantry Linear Planishers - Longitudinal Planisher

Small diameter tubular parts like bellows are perfect for our weld planisher designs. Perfect for thin tube planishing applications where strength and weld bead blending is specified. Special custom planishing machines for small diameter thin gauge metal bellows or tubes.

Gantry Longitudinal Planisher Machines

Planisher Applications

- Stainless Food Handling Equipment

- Dairy Equipment

- Bellows

- Chemical Process Tanks

- Stainless Pipe Fittings

- Missile Case Seam Weld

- Aeronautic Drop Tanks

- Automotive Sheet Splicing

- Tractor Wheels

- Cloth Dyeing Machinery

- Vacuum Thermos Tanks and Bottles

- Water Heaters

- Aircraft Engine Parts

- Drug Handling Machines

- Aerospace Parts

- Metal Furniture

- Cosmetic Seamless Welds

- Smoothing weld beads

- Seam weld cosmetic blending

- Increasing weld process strength

Our company has proudly been building gantry and longitudinal planisher machine designs for over 20 years in the USA. MITUSA special engineered seam welding planisher systems solve difficult planishing applications with automation. We know planishing machines and how to build one specific for your critical seam weld planishing application.

Table Top Planisher

Table Top Planisher

Planishing Benefits: Planishing roll process machines smooth out the seam weld beads for a blended ID and OD finish on the weldment up to 40 feet long. MIG, (GMAW) TIG, (GTAW) or Plasma Weld (PAW) – any low profile weld crown can be flattened smooth.

This advanced complete seamer system that can be customized for your specific welding application. This fuel tank seamer model was built for a petrol fuel tank truck length of 28 ft. Tank seam welding automation up to 40 feet of vessel seam welding length.

Longitudinal Roll Gantry Planishers

Planishing machine for smoothing away seam weld beads on the OD and ID of the part. This is done while keeping the part’s shape true before and after the planishing process finish.

Many aerospace and aeronautics weld seam specifications are now requiring the part to be planished after the welding process. Rely on MITUSA linear precision planishers to provide your company with more than you expected, when purchasing a planishing machine system solution.

MITUSA, Inc. Planisher designs are used on carbon, aluminum, stainless welded metal weld bean smoothing and seamless crown removal. Our company offers custom or standard gantry planishers and longitudinal planisher models. Let our engineering group design a custom planisher for your special planishing weld bead finishing application. Planishing is best used on thinner gauge metals, with low profile weld bead for maximum results. Challenge us with your planishing finishing application difficult applications, we can help.

Automated Planishing Machine | Weld Smoothing

Planishers are some of the most useful tools to improve welds cosmetic appearance of parts as well improving the welded metal joint’s strength. Welding planishers are often used for everything from aerospace parts and precision devices to common stainless steel kitchen sinks. The roll planishing machines provide safe automation of the weld finishing process. The common parts suitable for planishing systems include bellows, aerospace shells, flat plate sheet steel, cylinders, tubes, squares, domes, missile housings and other parts based on thickness of the weld bead crown profile.